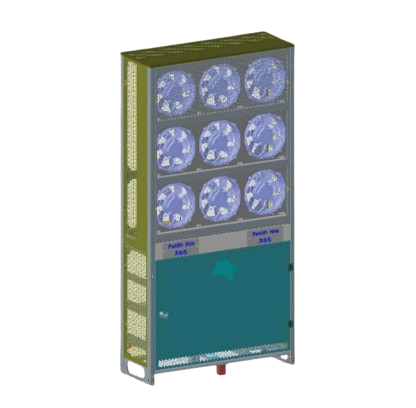

Grid Connected Battery Cooling Unit

Reynold India – Grid Connected Battery Cooling Unit

Introduction

In the era of renewable energy and electric mobility, battery energy storage systems (BESS) are playing a crucial role in ensuring uninterrupted power supply. However, efficient cooling of these battery systems is essential for maintaining their performance, safety, and longevity. Reynold India, a trusted name in industrial chillers and thermal management solutions, introduces its Grid Connected Battery Cooling Unit – an advanced, energy-efficient solution designed specifically for large-scale energy storage systems.

This article explores the features, benefits, and applications of Reynold India’s Grid Connected Battery Cooling Unit, making it the ideal choice for modern energy infrastructure.

Why Battery Cooling Is Critical for Energy Storage Systems?

1. Thermal Stability and Battery Safety

Lithium-ion and other advanced batteries are highly sensitive to temperature variations. Excessive heat can cause thermal runaway, leading to reduced performance or even safety hazards. Proper cooling ensures optimal thermal stability.

2. Extended Battery Life

Maintaining a controlled operating temperature minimizes battery degradation. With an efficient cooling system like Reynold’s, battery packs can last significantly longer, offering better ROI.

3. Consistent Performance Under Load

In grid-connected systems, batteries often undergo frequent charging and discharging cycles. A stable temperature ensures consistent performance and prevents overheating during high load conditions.

About Reynold India – Pioneers in Industrial Cooling

Reynold India, with over 29 years of expertise, is a leading manufacturer of industrial chillers and thermal management systems in India. Known for 12000+ successful installations across 60+ countries, Reynold continues to innovate with specialized cooling solutions for critical applications.

The Grid Connected Battery Cooling Unit is a testament to Reynold’s engineering excellence, designed to meet the demanding requirements of energy storage and renewable energy projects.

What is a Grid Connected Battery Cooling Unit?

A Grid Connected Battery Cooling Unit is a specialized chiller system designed to maintain optimal operating temperatures of large-scale battery packs connected to the electrical grid. These systems are integral to:

-

Renewable energy storage plants (solar, wind, and hybrid power stations)

-

Peak load management systems

-

Data center backup power systems

-

Microgrids and smart grid infrastructure

Reynold India’s unit ensures high energy efficiency, reliable cooling, and low maintenance, making it a preferred choice for utility-scale battery energy storage systems (BESS).

Key Features of Reynold India’s Grid-Connected Battery Cooling Unit

1. High Energy Efficiency

Equipped with advanced inverter-driven compressors and optimized heat exchangers, Reynold’s system ensures minimal energy consumption while delivering precise temperature control.

2. Wide Operating Temperature Range

The unit is designed to function efficiently in India’s diverse climatic conditions, from scorching summers to cold winters, ensuring reliable cooling 24/7.

3. Intelligent Control System

The integrated microprocessor-based control system provides real-time monitoring, fault detection, and remote operation capabilities.

4. Low Noise and Vibration Design

Specially engineered components ensure silent operation, which is crucial for urban and residential energy storage applications.

5. Eco-Friendly Refrigerants

Reynold India uses environmentally friendly refrigerants that comply with global environmental regulations, reducing the carbon footprint.

6. Compact and Modular Design

The modular configuration allows easy installation, scalability, and maintenance, making it ideal for expanding battery storage systems.

Technical Specifications (Typical)

(These can be customized as per project requirements)

| Parameter | Specification |

|---|---|

| Cooling Capacity | 20 kW to 500 kW |

| Temperature Control | ±1°C precision |

| Refrigerant | R-134a / R-407C / Eco-friendly options |

| Power Supply | 400V, 3 Phase, 50Hz |

| Connectivity | Remote monitoring & BMS integration |

| Operating Ambient | -5°C to +50°C |

Applications of Reynold’s Grid-Connected Battery Cooling Unit

1. Renewable Energy Storage Plants

Solar and wind power plants rely on large battery banks to store energy for grid stabilization. Reynold’s cooling units ensure these batteries operate within safe temperature ranges, improving efficiency and reliability.

2. Data Centers and Critical Infrastructure

Backup energy storage systems in data centers demand uninterrupted power and strict thermal control. Reynold’s cooling solutions ensure zero downtime and optimal battery performance.

3. Microgrids and Smart Grids

For rural electrification and smart city projects, battery cooling plays a vital role in maintaining system stability and extending the battery lifespan.

4. Electric Vehicle (EV) Charging Stations

Grid-connected BESS installed at EV charging stations require effective cooling to manage high charging loads. Reynold’s cooling system ensures consistent performance in such demanding environments.

Advantages of Choosing Reynold India for Battery Cooling

1. Proven Expertise

With decades of experience in industrial cooling, Reynold offers reliable and tested solutions that meet international quality standards.

2. Custom-Built Solutions

Reynold designs tailor-made cooling systems as per project requirements, ensuring perfect integration with the battery energy storage system.

3. Nationwide Service Network

With a strong service network across India, Reynold ensures quick installation, commissioning, and after-sales support.

4. Energy-Saving Technology

Advanced energy-efficient components and intelligent controls reduce operational costs and improve the ROI of energy storage projects.

Why Grid-Connected Battery Cooling Matters for India’s Renewable Future?

India’s renewable energy sector is growing rapidly, with ambitious targets for solar and wind power. Battery Energy Storage Systems (BESS) are essential for grid stability, peak load management, and ensuring round-the-clock renewable power supply.

However, without proper thermal management, batteries face:

-

Reduced efficiency

-

Faster degradation

-

Safety hazards

By deploying Reynold India’s Grid Connected Battery Cooling Unit, energy companies can:

-

Improve battery life by up to 30-40%

-

Enhance energy storage system reliability

-

Achieve faster project ROI

Case Study – Successful Deployment

(Optional section – can be expanded with real data later)

A leading solar power plant in Rajasthan integrated Reynold India’s battery cooling units into its 10 MW battery energy storage system. The results included:

-

Improved battery cycle life by 25%

-

Temperature is maintained at an optimal 25°C even during peak summer

-

Significant reduction in energy consumption due to inverter-driven cooling technology

Future of Battery Cooling in Energy Storage

As energy storage systems evolve, cooling technology will continue to play a critical role. Future trends include:

-

Integration with AI and IoT for predictive maintenance

-

Hybrid cooling solutions combining air and liquid cooling

-

Use of natural refrigerants for environmental sustainability

Reynold India is actively working on developing next-generation battery cooling solutions to meet these future demands.

Conclusion

The success of battery energy storage systems depends significantly on efficient thermal management. Reynold India’s Grid Connected Battery Cooling Unit provides the perfect blend of reliability, energy efficiency, and cost-effectiveness for modern energy storage applications.

With 29 years of expertise, 12000+ installations, and a commitment to innovation, Reynold India stands as a trusted partner for industries, power plants, and renewable energy developers seeking world-class battery cooling solutions.

Get in Touch with Reynold India

Website: www.reynoldindia.com

Email: chillers@reynoldindia.com

Phone: +91-9971396904

Factory: Building C-38 & 39, Sector-2, Noida, Uttar Pradesh 201301

Social Media: LinkedIn | YouTube | Facebook | Instagram

Read This Also

Chiller Efficient Battery Thermal Cooling Performance Optimization System Management

Refrigerant Gas R-22 & R-407C For Chillers

Compact Portable Auxiliary Cooling Chiller Systems

Temperature Sensor MCS, LP Switch, HP 200 to 500°F TI-100 For Chiller

Oil Heating and Cooling Machine Equipment

LP HP DP Gauge Switch for Chillers