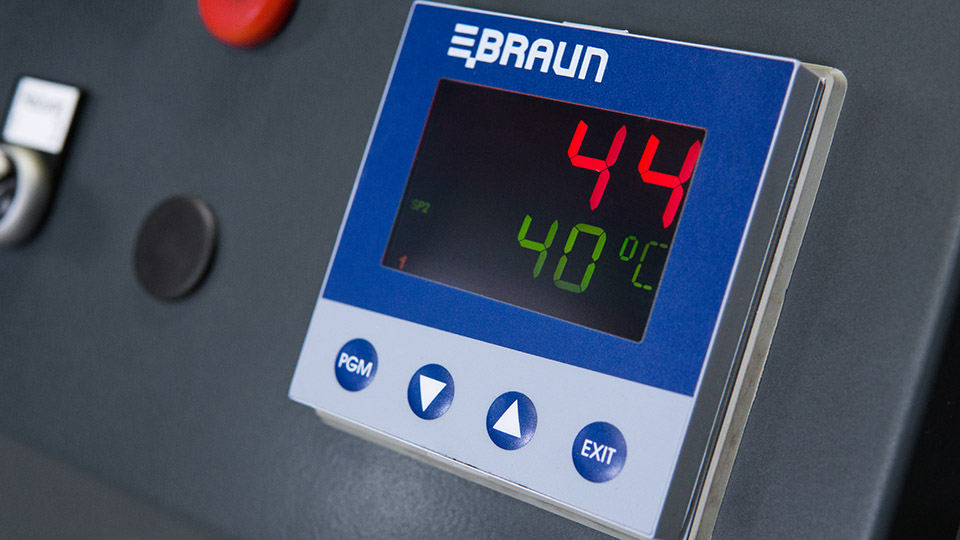

Temperature- control units

We supply standard temperature control units, but also specially adapted pulse and alternating temperature control units as well as testing systems.

Temperature control units must support the injection molding process and the optimized mold temperature control with special functions. Only in this way is it possible to produce the optimum part quality with short cooling times and low resource consumption.

SPECIFICATIONS

Compact designs Simple handling via touch screen Process controller with temperature monitoring and self-optimization Various memory and program functions Interfaces for machine controlling Non-contact flow measurement with power display Wide range of pumps Stainless steel heat exchanger Bypass cooling / bypass valve Mold emptying by means of compressed air

TEMPERATURE CONTROL UNITS (WATER)

| Model | Heating/Cooling power [kW] / [kW] 90 °C | Pump capacity [l/min] | Heating temp [°C] | Filling volume[l] | Connections [Zoll] | Dimensions w * d * h [mm] |

|---|---|---|---|---|---|---|

| BW-130-24 | 3 / 12 direkt | 27 | 100/120 | 4 | 2 x R½ / R½ | 195x350x360 |

| BW-180-9 HF-BK | 3 / 12 direkt | 27 | 100/120 | 4 | 2 x R½ / R½ | 195x350x360 |

| BW-180-12 HF-BK | 3 / 12 direkt | 27 | 100/120 | 4 | 2 x R½ / R½ | 195x350x360 |

TEMPERATURE CONTROL UNITS (OIL)

| Model | Heating/Cooling power [kW] / [kW] 90 °C | Pump capacity [l/min] | Heating temp [°C] | Filling volume[l] | Connections [Zoll] | Dimensions w * d * h [mm] |

|---|---|---|---|---|---|---|

| BT9OT-HF | 9 / 18 ind. (150 °C) | 55 | 150 | 11 | R¾ / R½ | 300/570/630 |

| BO 250-9 HF-BK | 9 / 25 ind. | 60 | 250 | 11 | R½ / R½ | 385/1055/900 |

| BO 250-12 HF-BK | 12 / 25 ind. | 60 | 250 | 11 | R½ / R½ | 385/1055/900 |

| BO 250-18 HF-BK | 18 / 25 ind. | 60 | 250 | 18 | R½ / R½ | 385/1055/900 |

| BO 250-24 HF-BK | 12/24 / 25 ind. | 60 | 250 | 21 | R½ / R½ | 385/1055/900 |

| BO 300-12 | 12 / 25 ind. | 60 | 300 | 18 | R½ / R½ | 385/1055/900 |

| BOD 250-18 | 2 x 18 / 2 x 25 ind. | 2 x 60 | 250 | 2 x 15 | R½ / R¾ | 690/1000/1050 |