ABOUT AMBOSS +LANGBEIN

Established in 1984, Amboss+Langbein GmbH & Co. KG is a German company headquartered in Haan. They provide a comprehensive solution to the needs of plastics manufacturers. With a vertical range of products spanning from cabinets and dryers for granulates, dosing units, blenders and loaders for automated processing of bulk material and plastic pellets as well as proprietary conveyor belts. With more than three decades in the field,

Amboss+Langbein has cemented itself as a company that provides a wide range of high ends products. Through their in-house manufacturing, and automated production as well as technical expertise, Amboss+Langbein also provides customer-oriented problem solving and solutions that are tailored to individual customer needs. With an aim to bring German engineered auxiliary equipment to the plastics industry in India. Amboss+Langbein and Reynold India joined hands in 2020 to offer the same.

Hopper Loaders Z-F series

Hopper Loaders Z-KR, Z-KR 2 und Z-KR 3

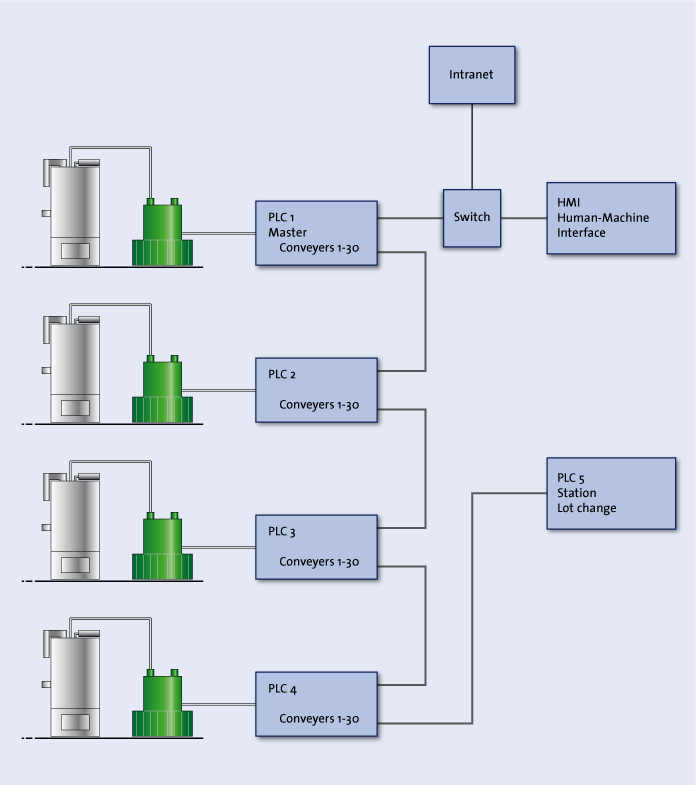

Control of conveyance systems

System layout

Auto Loaders Conveying Systems

Manually. automatically, by dry air, with external motor - anything goes ! We take your material to where you need it! Whether you want to feed your material manually or automatically, whether the material is fine, coarse, non free-flowing, or highly abrasive – we have the solution for you. At Amboss+Langbein, we use proprietary, patented glass pipe segments that are wear and break resistant and highly durable.

Read More

Centralized Conveying System

On the safe side With the conveyance systems at Amboss+Langbein, hopper loaders are filled according to the “First in, First out” principle. Amboss+Langbein guarantees a transport capacity of c. 200 metres. The material throughput can reach up to 1.5 tonnes per hour. A dual bus cable design results in high operational reliability for the Amboss+Langbein hopper loaders. Our central system allows up to four vacuum circuits to be managed automatically, with capacity for up to 120 separators to connected to the system. An emergency motor design ensures trouble-free operation even in case of vacuum generator failure.

Read More

Mixers at Amboss+Langbein

Just right for uniform mixtures Mixers are suitable for downstream blending of granular particles directly at the processing machine (injection moulding or extrusion).

Read More

Two-component proportional valve MIVE11