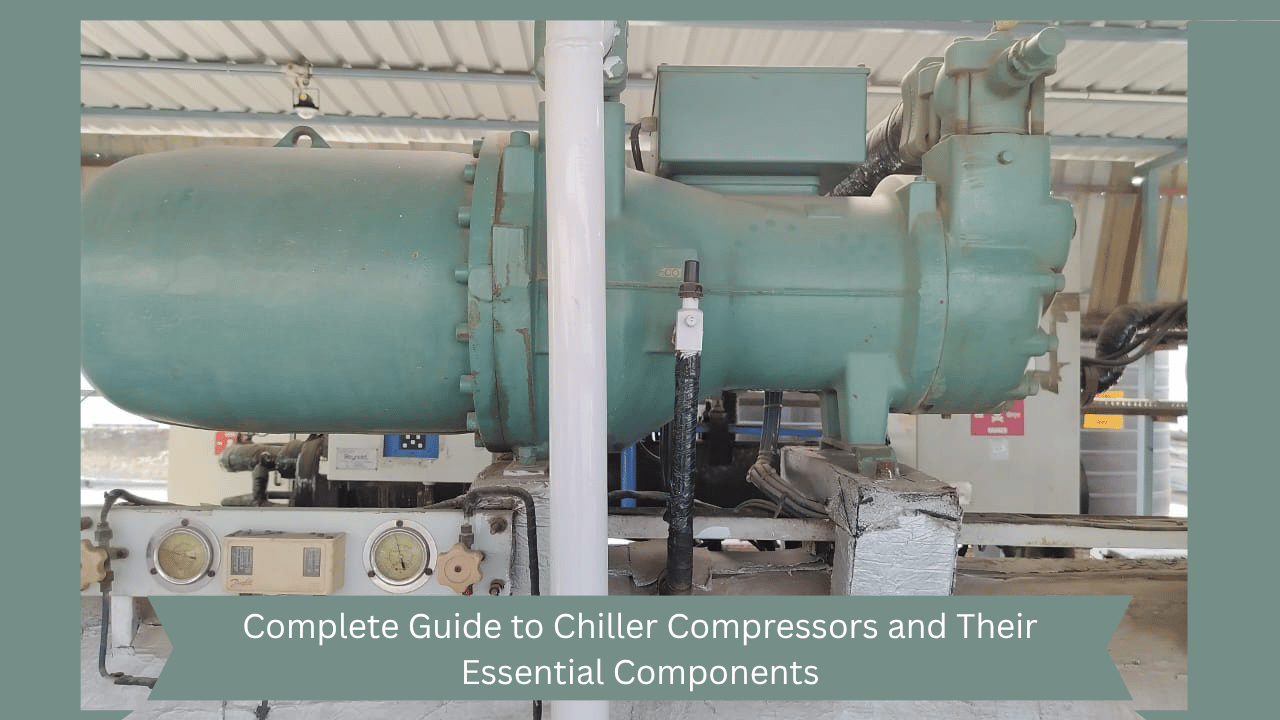

Complete Guide to Chiller Compressors and Their Essential Components

Chillers are the backbone of modern industrial cooling systems, and at the heart of every chiller is the chiller compressor. Whether it’s a scroll, screw, or centrifugal type, the compressor is responsible for maintaining efficient cooling operations. In this blog, we’ll dive deep into the compressor for chiller systems, along with other vital components like the mechanical seal, compressor oil, filter core, and more.